|

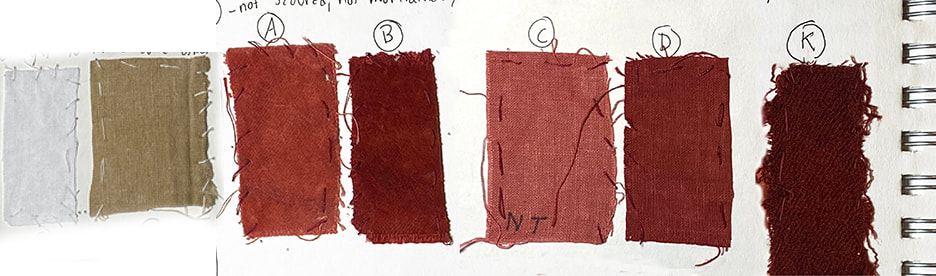

Doing a madder dye pot is something of a long term commitment! There is so much you can get out of it, if you do everything just right. Madder is a plant, the dye color comes from the root, and you can’t harvest the root until the plant is at least 3 years old. The root from the madder plant can make my favorite color in the world-a rich, warm dark red. Madder can also make orange, pink-or brown if the temperature gets too high. The leftovers from the dye bath can be precipitated into a solid pigment (see my 4/29/22 post “Don’t Jump in this Lake”) from which can be made pretty much any kind of paint-oil, watercolor, gouache, pastel, egg tempera etc. The ancient Egyptians used it, the Greeks and Romans used it, it was very popular in the middle ages, Renaissance…and some version of “Madder Lake” or “Rose Madder” has been in my paint box from when I started painting many moons ago until now. All of the above-from antiquity to me-used madder both to dye fiber/fabric and to make paint. You need a lot of madder to get the strong red that’s my favorite color. I’ve had a beige (what was I thinking-me-beige???) sweater, ramie and cotton, for literally decades. One of the reasons I never wear it out is that I don’t wear it much. It fits great. It’s comfortable. But…I’m just not a beige sort of person. I decided that in this dye pot, I would solve two problems; the beige sweater, and getting a rich red on cellulose, which would be for example cotton, linen, hemp bamboo etc., that is vegetable and not an animal fiber like wool. Wool soaks up madder like a sponge, think of the wool Persian carpet reds, they historically used madder for those. But I have repeatedly failed to get a decent red on cotton. I have to admit, if I ever wanted something in pink, the pink from madder is really lovely. But I don’t want pink, I want that deep intense red. So, this time, I pre-treated my sweater and other cellulose fibers with oak galls; anything with a high tannin content would do, but oak galls are as good as it gets with a natural tannin. Black tea has tannin, pomegranate skins have tannin, so does the oak leaves, bark and other parts, but the galls-the tree’s defense agains a wasp-have more concentrated tannin that doesn’t discolor as much, or at least that’s what I’ve read. In fact, when I pre-treated with the oak galls it turned the fabric tan. BUT-I finally got good reds from cellulose! Look at the swatches! I tried several fabrics both with and without the tannin pre-treatment, and the results speak for themselves. And the sweater is now a lovely color-I can’t wait until it’s less than 90 degrees and 100 percent humidity to wear it.  If you look at the swatches A & B also C & D are the same fabric, dyed in the same dye bah for the same time. The difference was B & D got pre-treated with tannin from oak galls. Far let, same fabric as C & D, showing the natural cotton hemp fabric far left, and treated with tannin next to it. K is wool that was in the bath less time than A-D, showing the super deep red.  After a chemical reaction to precipitate the dye into a pigment, the hard work is getting rid of the water to make a dried pigment. In the smaller clear container upper left, you can see how the pigment is collecting in the filter, and the clear liquid accumulating below. Same thing is happening in the big bucket, I'm using fabric in a kind of colander as my filter. Far right, you can see the pigment spread out to dry on a pane of glass. See 4/29/22 post for more on this process It’s not unusual to keep a madder dye pot going for a week or more. You bring the temperature up to 150-160 degrees F. for 10 minutes to an hour, then let the fabric sit in the warm pot, day after day, until it gets to the depth of color you want. At a certain point, the fabrics just don’t get darker. At that point, there are choices. You can get lighter colors, you can add something acidic to get orange-or you can make the leftovers into a pigment. I didn’t have things I wanted to dye rose or orange, so I made a lake pigment. I’m very curious to see how the color will compare to the lake pigment I made this past winter.

But wait, this is madder, so that’s not it. I strained the roots out of the dye pot before I made the lake pigment. Today, 11 days after I first began working with those roots, I put them in fresh water and started a new dye pot. Like I said, madder is a long-term commitment. Too long for one blog post, I’ll have to post again to let you know what happened with round two of madder dye pot #8. I keep a “dye-ary” of all my dye pots, and so I know that yes, this is the 8th madder dye pot I’ve done so far.

0 Comments

Leave a Reply. |

Cindy VojnovicArtist & Educator Archives

September 2025

Categories

All

|

RSS Feed

RSS Feed