|

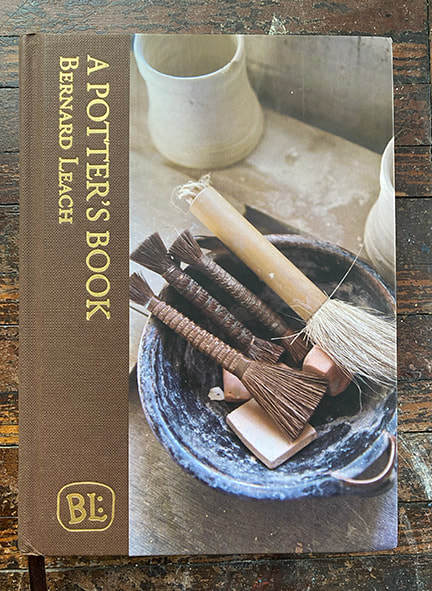

When I began working in ceramics all those years ago (the 1970’s!) I can recall being disappointed, first in high school and then in college, at the “lack” of color in the available glazes. We all had our boxes of crayons bursting with color, and even the cheapest mass-produced consumer goods were glaring with color. Even today, consumer goods (even foods) are bursting with artificial color. We inhabit mostly a built environment (how often are you out in nature?) where a cacophony of accidental color prevails. For example, I’m thinking of a very tastefully designed lounge, with all the furnishings and carpets and such color coordinated-inhabited by people sporting all kinds of colors, carrying bags and things with even more crashing colors that were most decidedly not a part of the designer’s scheme. I think we learn to ignore all these clashing colors as some kind of self-defense mechanism. I have to admit, it could be age. But it could also be looking at lots of great pottery-Bernard Leach, Shoji Hamada, Michael Cardew, Phil Rogers, Matthew Blakey and plenty of works by unknown potters in museums-I’m coming to appreciate the palette of winter. It’s like a palette cleanser for the eyes. For me, the browns aren’t neutral. Some are russet, some cool, some tawny, and these browns are punctuated (some days) with blue sky, and evergreens wearing their dark green winter coats. And when it snows, the blue sky is replaced by white, silver and a range of greys as varied as the browns they cover, to varying extents depending on how much it snowed. Don’t get me wrong, I still love the deep saturated colors of medieval stained glass, for example, but I’m also appreciating the subtle symphony of colors that winter offers. Even as a child I loved drawing bare trees, fascinated by the spooky dark trunks and branches, the more gnarled the better. But the NCC East 40 is mostly meadow. The mountains, ocean and even forest that I always tended to associate with “nature” just are not there. Much like the winter palette of colors, which I’m enjoying more and more, I’ve come to appreciate the subtlety of the forms of the meadow. Today a new revised reprint of Bernard Leach’s classic tome “A Potter’s Book” arrived. This edition has color versions of most of the pottery examples, and they are very much in keeping with the winter landscape.

Right now I’m perfectly content to inhabit the colors of winter.

0 Comments

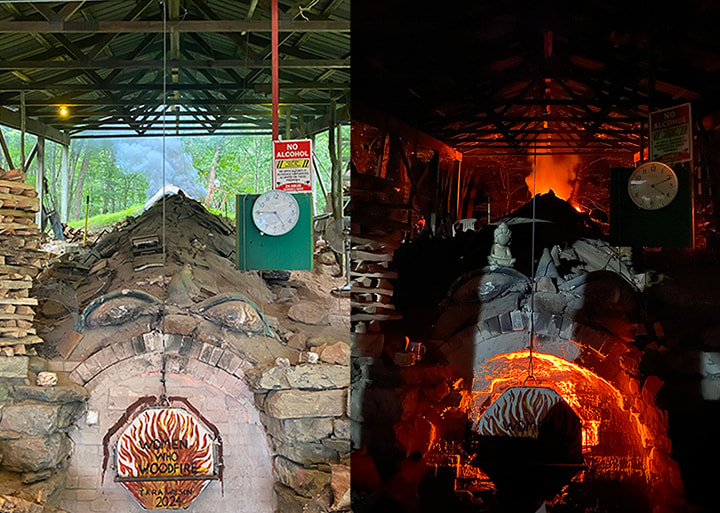

Please note: these videos take a while to load. (Having technical problems and don't have enough hours to throw at solving them right now) The burn ban was finally lifted, and on December 18 we finally began the firing. The two anagama firings I did in August and October went on for 5-6 days; but this firing was scheduled to be completed in just over 24 hours. To get the work “fully cooked” meant that we had to actually reach higher temperatures in the kiln than would be the case if we were firing over many days. The cones behind the removable bricks were our only way we could be sure when the work in the kiln was fully “cooked.” The heatwork needed to achieve cone 10, our goal, is considered to be 2,381 degrees. That level of heatwork can be reached by more time at over 2,100 degrees, but for a one day firing we were going to need all 2,381 degrees to get cone 10 to bend over. Gabby Gentile and Connor McGaughran (my student worker at ESU) had been there since 2 in the afternoon, and stayed with me well past their points of exhaustion until after Dave Graham (Kiln Building Guru) was able to join me. With two fireboxes needing to be stoked every few minutes, this was a skeleton crew. It was after midnight that Gabby and Connor finally went home, and it was just Dave and I for the rest of the night, until the end of the firing the next morning. I took the left firebox, and Dave the right. It’s crazy how kilns have a personality, and how two fireboxes that should be identical, one right next to the other, can behave so differently. The left side of the kiln runs colder, the coals don’t burn down to ash fast enough, so the left firebox can get so choked with coals that it restricts the needed airflow on that side. How much, what size and what kind of wood to put in, and when, are decisions that are constantly being made. You don’t just chuck wood into the kiln and hope it works; this too is an art. Pine combusts faster, but doesn’t have the staying power of hard wood, it’s kind of like a sugar high, you either feed soft wood constantly or it can crash. Hard wood can actually make the temperature drop while it’s trying to combust. Likewise, the thinner the wood is cut, the faster it catches fire-and burns out. Getting the right mix of types and sizes of wood, how much room you leave open in the firebox, how often you stoke-all this has to be right, or the kiln will let you know. There’s a wonderful “roar” when a kiln is really hot, and it’s happily digesting just the right amount of wood. The night was beautiful. It would have been cold being out all night like that, but the kiln generated so much heat that being so close, I didn’t need most of the layers of clothing I had brought. The wind was going in the right direction, I think it actually helped us. Pyrometers that measure the air temperature in the kiln are not terribly accurate at the higher temperatures, but they do let us know if the kiln is getting hotter or cooler, which is critical information for figuring out when to stoke for example. As the kiln heats up, everything wants to expand. I’m glad Dave was there when one of the steel tie rods holding the kiln together popped under the pressure! Wow, that made me jump. He had just replaced the tie rod above the one that broke, and assured me it would be fine. You could see the other tie rods bow with the pressure the kiln was exerting as it expanded, but they held. Even if we hadn’t had the pyrometers, as in olden times, you can really tell when a kiln gets up to those higher temperatures well in excess of two thousand degrees! At 9 something in the morning, Cone 10 had made it’s perfect arc on the top right, and both cone 10 and 11 weirdly were bending together on the bottom left; we got to our goal. Once we reached our cone 10 goal, we stuffed the fireboxes as full as we could get them, then shut off all access of air to the kiln. Kilns go crazy when you do this! Any tiny sliver of space, around a brick, around a door, the flame tries to reach out, gasping for oxygen. That’s when you walk around the kiln-any gaps anywhere become really obvious with flame shooting out of them! The “door” of the kiln is temporary, rebuilt for every firing, so flames shooting out from there are not a problem. But if places that should be tight open up, this is when you find them. The fire just burns itself out, smothers-then you have to wait, and wait, for it to cool down. The bigger the kiln, the better insulated it is, the longer it takes. This post is already way too long, so you have to look at my next post for the unloading!

A delightful part of my part-time job as Manager of Ceramics at the Northampton Community College (NCC) East 40 is firing the wood kiln there! I had fired that kiln a number of times before, but for this Fall’s firing, I took on more of the work than in previous firings. I made the cone packs, for example, and made more of them than we had ever used in a single firing. Cones are scientifically formulated to bend over at very specific levels of “heatwork.” Heatwork is a matter of both time and temperature. The example I always give is lasagna. The oven may be 400 degrees, but if you only leave the lasagna in for five minutes, it’s not going to be cooked through! On the other hand, even if the oven is only 350 degrees, if you leave it in for 40 minutes it’s probably going to be fully cooked. Cones measure to what degree the ceramic is “cooked,” much like how a meat thermometer measures the temperature of the meat itself, not just the air in the oven. It was the first time I actually got to load a wood kiln, which takes a surprising amount of skill, not to mention hoisting really heavy silicon carbide shelves into place. All the hours I had spent watching others load wood kilns was invaluable. The idea is to understand how the flame moves through the kiln, and much like playing pool where one ball bounces off another, you want to bounce the flame onto all the pots, ideally send the flame everywhere, reaching every pot without restricting the path through the kiln. No pot can touch, or even get too close to touching, yet you have to do a kind of Jenga where you get as much work into the kiln as possible. The way ash moves through and lands on the work is another consideration. Suffice it to say it was an honor, and I was holding my breath that certain decisions I had made would work out! For example, Kelly Allen noted that no one had ever put the center shelves as far to the front as I had. Yikes! I was hoping for better flow through the kiln, more ash, but what if it just meant that the work closer to the front door didn’t get hot enough? Gulp. The door for the kiln gets built for every firing! First, the bricks. I actually really enjoyed custom fitting the last brick at the top of the arch, you can see it’s a lighter color than the bricks next to it. In previous firings we had done two bricks that stick out beyond the others, so you could remove them and see the cone packs strategically placed in the kiln for that purpose. For this firing, in addition to the two “peep” bricks, a third one with a hole in the middle was set up as a “blow hole.” Long story short, when flame is no longer coming out of the blowhole, you know it’s time to stoke. After the bricks were in place, Gabby Gentile (professor at NCC) and I “mudded” the door, which is pretty much like it sounds, although we used wet reclaim clay, not the kind of mud you have in a garden. Nothing like hands wet with “mud” in the winter. Then, for extra help so not so much heat escapes from the “door,” a special high-temperature cloth that looks like cotton but is not flammable, supported with a wire mesh was placed over the door. The pots were all loaded, the kiln was ready; but we had to leave it like that for weeks waiting for the burn ban to be lifted.

Even without the added eyeballs and horns, the anagama kiln at Peter’s Valley would look like a dragon. It only gets fired once per year, it takes a lot of wood and a lot of people power to fire this 57 foot long kiln-and that’s exactly what I was up to for this past week. As I write this, the kiln is cooling down, I will post again after the unload which is coming up this Sunday. I worked nights, and hung out during the day as much as I could when I wasn’t sleeping. The workshop was led by the Tara Wilson, an amazing artist with a trove of woodfire experience. Charlie Lid was on overnights (among a lot of other things), a veritable brain trust who has fired this kiln 22 times and made repairs to it. The staff at Peter’s Valley is awesome, all in all it was a great group of people. From loading to finishing was all interesting, but my favorite part was the overnight crew firing the kiln. Each night got hotter, and the last night was just nothing short of magical. We were giving the kiln exactly what it wanted (with Charlie’s interpretations) and it responded. In a few hours, we side-stoked over 900 pieces of wood, and that not counting what was put in the main firebox at the mouth of the kiln. There was music on, and all of us at some point were literally dancing; there was so much joy, we were dancing with the kiln. It’s an experience I will never forget. It’s hard to come up with words that describe the sheer power and elemental force of the flames within the kiln, that on that last night refused to be contained by the lids on the stoke holes, or the damper at the end of the kiln. Note that in the above photo and video, there is nothing “open” on the kiln; there are lids on the stoke holes and a big solid damper covering most of the end of the kiln-but the fire was so powerful that after we would stoke, it would erupt like a volcano from the slightest of gaps.

In my first post on my new series of Medieval inspired ceramics, medieval-inspired.html I wrote that “So far only a few of these pieces been glaze-fired.” I think one of the strengths of this whole series is the interaction between a traditional thrown form with decorative/geometric/abstracted elements and incomplete figurative elements. An essentially one-color glaze keeps the ambiguity and imaginative leaps that the viewer can enjoy. I have come up with two strategies for making the glazes have some depth, variety and interest without getting contrived looking; local (and sometimes wonky) materials and wood kiln firing. As you can see from the vase above, glaze is not always going to hugely change the look of the piece. Even with the different background, lighting and point of view, this vase didn’t change its essential character when glazed. I formulated the glaze that I used featuring rock that I picked up off the side of route 611 in Easton. You might think that I could have used just any white glaze; but look closely at the comparison photos below. On the left, the vase was glazed with the glaze that I inherited in the ESU studio, with all commercial ingredients. On the right, another vase glazed with my rock glaze; I know it’s not a huge difference, but I prefer the rock glaze. So on the one hand, the glazing doesn’t necessarily radically alter the look of the piece from its pre-glazed state. But on the other hand, the glaze-and how it’s fired-really do matter, and give not only practical advantages like hardness and waterproofing, but improve aesthetics as well. The vases above were fired in an electric kiln; the first post I made about this series showed work that was fired in a one-day wood kiln firing. Wood kiln firings can have many serendipitous effects, between wood ash landing and melting onto the work (that was probably how glaze originated) fire hitting the work and the reduction atmosphere which causes both the clay and glaze to achieve different effects. The longer the firing, the more wood ash you are going to get, which is one of the reasons I’ve held off firing a number of my pieces; I will be taking the Anagama Wood kiln firing workshop at Peter’s Vally next month, where I can bring 30 pieces! Whether I’m using rock glazes or wood kiln firing (or both) my goal is the same; I want natural effects, not contrived painting/coloring.

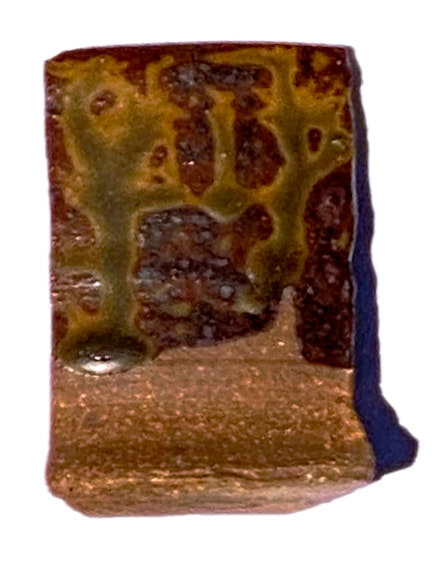

Vase made from the new clay body featuring East 40 clay. You can see the clay with no glaze at the bottom, and where I did strokes of wax resist as seen on the view to the left. A glaze featuring the East 40 clay was used at the top of the pot, you can see it's darker than the glaze below the neck of the pot.. As promised, some results from the test kiln firing. After making the part 1 post, I realized that it was just too technical for a blog post. I reached a kind of crossroads where I realized I needed to create a section of the website for technical information. If you want something more in depth than this post, go to my new Ceramics-Technical page, and the pages that branch off of it. The little test kiln did reach cone 10 (approx. 2,381 F) but not without a battle of many hours in the sweltering heat. Luckily, it was worth it. The firing gave us really critical information; how will the new clay body behave at high-fire temperature in reduction (oxygen starved) kiln atmosphere, which is how we fire the wood kiln? And, how will the 25 glaze recipe variations with the East 40 clay look and behave on the new clay body? Overall, the results were a smashing success. Both clay body, glazes, and the way the glazes look on the clay body passed with flying colors. Again, I'm not going to go into all the technical results here, but I do want to show you some of the highlights of what came out of the little kiln. In the test bars above, you can see the color of the clay with no glaze for yourself. In addition to the tile in the test kiln firing, the dark one at the bottom of the photo, Gabbry Gentile was kind enough to fire the one on top in the electric kiln up at the ceramics studio in Penn Hall on the main campus. I formulated this clay body for high temperature firings like we do in the wood kiln at the East 40; the real shocker, was that this clay body works at the medium range temperature used in the studio on campus! I won't go into the technical details here, but suffice it to say I was honestly shocked at how well this clay performed in an electric kiln at mid-range temperature! Ash glazes are supposed to show dramatic drips; the trick is, you don't want them to run off the pot. This test tile was photographed on its back because of sun glare, but it was standing up on vertical when fired in the kiln. The pleasant surprise was that all the variations of the ash glaze stayed up on the tile, none of them ran off the tile at the bottom which is a big problem with a lot of ash glazes. Many ash glazes can only be used at the top of the pot, they are so runny. This was the runniest variation, and even it didn't run off the tile. Long story short, we already have usable glazes based on the East 40 clay and wood ash, and they work great on the new clay body! Above is the simplest glaze recipe I tested-and my favorite result! The drips are less dramatic without the eggshell. It's such stable glaze that I can see using it on an entire pot, not just at the top for a drippy effect. The color comes primarily from whatever is in the East 40 clay, educated guess, a lot of iron.

Getting back to the vase at the top of this post, the dark part at the top is the same as the tile above, except there is an addition of copper oxide. The pot was first dipped in a glaze we had on hand from previous wood kiln firings, we wanted to see how it worked on the new clay body. The red you see, especially on the view to the right is actually from the copper-rich glaze I was testing at the top! All in all, we got lots of very helpful information from the test kiln firing. In all honesty, I didn't expect this much success in a first time at full-temperature firing!  Interior of the wood kiln at the Stahl's Pottery. You can see where the flame, heat and smoke came up from the 4 fire boxes in the floor; the pottery was put into other plain pots called "saggers" which were stacked floor to ceiling before the kiln was fired. 16 vents in the roof provided a draft to the chimney. I had two main reasons for going to the bi-annual Stahl Potter festival on June 15. One, I found out James Chaney, who I studied with 1978-80, was going to be there and I just had to tell him in person how great his instruction had been, and how I was building on it all these years later. The other of course was to see the historic pottery, and in particular the wood burning kiln.

Not long after I met the man who has now been my husband for 25 years, he asked me what kind of architecture I liked best. It’s not a question anyone had asked me before, but my pause was under a minute; Victorian Gothic. What might practitioners of Victorian Gothic such as A. W. Pugin or John Pollard Seddon, for example, possibly have to do with a Pennsylvania Dutch Pottery-or Colonial Revival for that matter? Yes, I know this seems very fractured, but it was the trip to Stahl’s Pottery, and reading the book “Stahl’s Pottery of Powder Valley” that connected the dots. My mother despised all things Victorian and idolized all things colonial, so that adds a family historical twist to this aesthetic conflagration. Let me begin to unpack this aesthetic cacophony. The book has a chapter “Arts and Crafts and the Colonial Revival” and the “Arts and Crafts Movement” was invoked on multiple occasions as I toured the pottery and museum. When I think “Arts and Crafts” I think of 19th century and especially British artists; William Morris and Edward Burne-Jones for example, and if American, maybe Gustav Stickley, not of Colonial American revival. But there are commonalities, and my visit to the Stahl pottery got me thinking about them-and my own heritage. It’s easy to think of any revival, be it Victorian Gothic, Colonial or Arts and Crafts Movement, as an imitation; as something less-than the original. But William Morris, whose designs are still popular, did not simply copy older prototypes-he made new designs for a new age, an age that keenly felt the loss of the individual craftsman in mass-manufacture. (It’s a bit mind-breaking that mass manufacture is overwhelmingly how those of us in the twenty first century have ready access to his designs.) And that was the big epiphany-that these “Historiated” styles, when done right, are new inventions originating out of the needs and circumstances of their own times, not less-than imitations of something that is done and over. The Stahl brothers learned pottery from their Victorian father. In the early twentieth Century they shut down the pottery they inherited/tried to carry on from their father, because they couldn’t compete with mass-manufacture. But they opened their own pottery three decades later because the values of the Arts and Crafts movement begun in the nineteenth century had taken root here, in the twentieth century, and the literal value of the kind of work they had done for their father had multiplied. In the midst of the Great Depression no less, the Stahl bothers opened an old style pottery with wood kiln, what is now the Stahl’s Pottery Historical site https://www.stahlspottery.org. I didn’t see my mom’s fascination with the colonial as more than her personal taste; I didn’t see it as part of a larger historical phenomenon. My mother seldom could use the word “Victorian” without the accompanying adjective “monstrosity.” (I suppose my way of rebelling against my mom was a Victorian aesthetic.) I was missing the through lines, of Arts and Crafts, Colonial Revival and my own aesthetics. The Stahl brothers weren’t imitating the work of previous potters; they were doing their own work. The interesting thing with arts and crafts is that when you do things with your own hands, it’s actually hard not to put yourself into what you’re doing, even if you’re using traditional materials and techniques. And those who pick up those pots, or look at those paintings or wear that hand knitted sweater etc. see that human element, which only becomes more precious the more impersonal products become in our society. |

Cindy VojnovicArtist & Educator Archives

September 2025

Categories

All

|

RSS Feed

RSS Feed